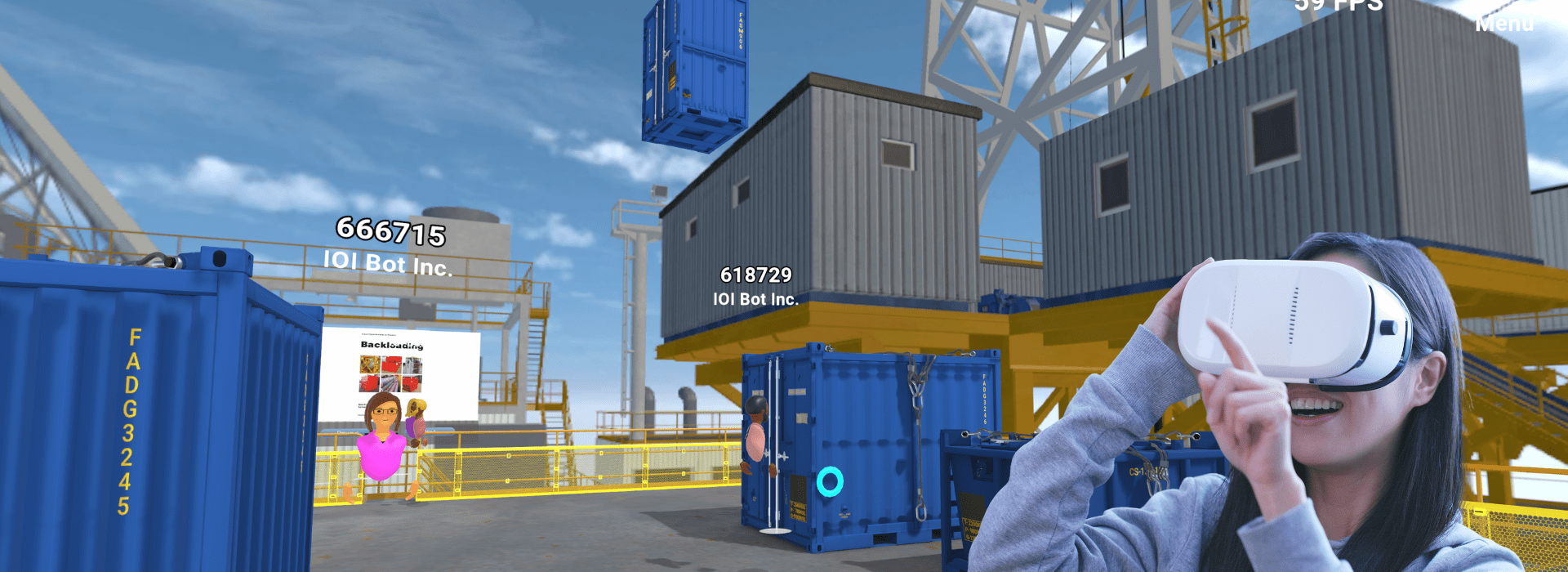

In industrial settings, especially elevated platforms like offshore rigs or construction sites, the looming threat of dropped objects is undeniable. These hazards span from immediate dangers, such as injuries or fatalities, to equipment damage, operational disruptions, and financial implications. The Hierarchy of Controls provides a structured pathway to navigate and mitigate these multifaceted risks.

Animation by Reuzer

Elimination: The First Line of Defense

At the pinnacle of the hierarchy, elimination is the most effective strategy. It’s about rethinking processes and workspaces. For instance, redesigning a process so that certain tasks are done at ground level can eliminate the risk of objects being dropped from heights. A practical example includes the removal of metal riveted name plates on drilling equipment, ensuring no risk of it falling.

Substitution: A Safer Alternative

When elimination isn’t an option, substitution comes into play. This involves replacing a potential hazard with a less risky alternative. Transitioning from older, weighty lighting systems to lightweight LED versions not only offers energy efficiency but also reduces the risk if they were to fall.

Engineering Controls: Physical Barriers and Solutions

Engineering controls focus on modifying the physical environment or the way tasks are performed. For dropped objects, this could involve using tool tethers or installing barriers on elevated platforms. Ensuring that equipment at elevated positions is securely anchored can also reduce the risk of them becoming potential hazards.

Administrative Controls: Shaping Behavior and Processes

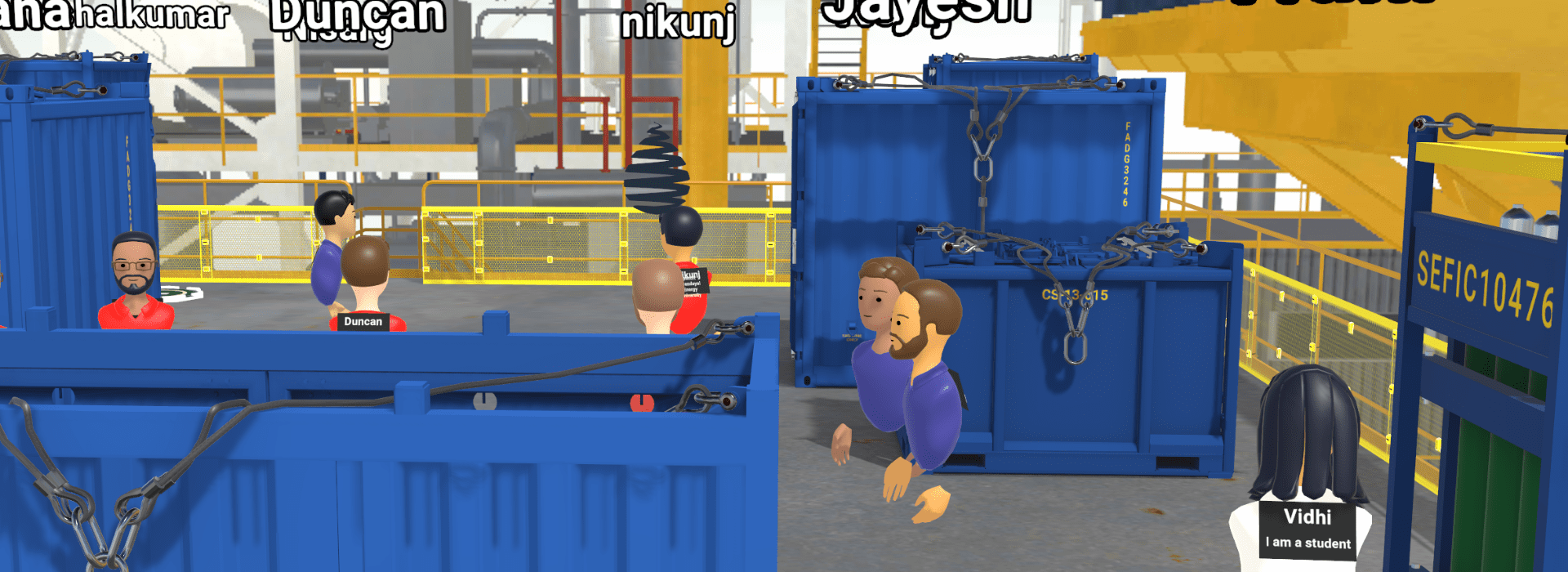

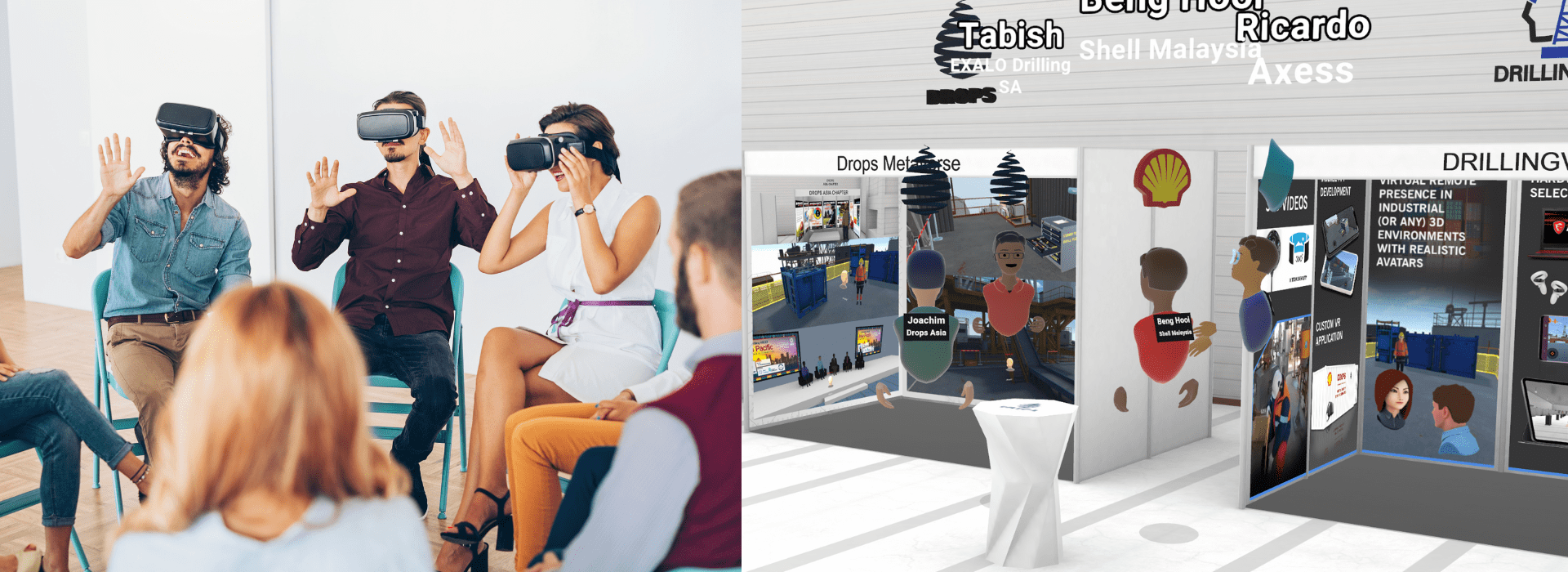

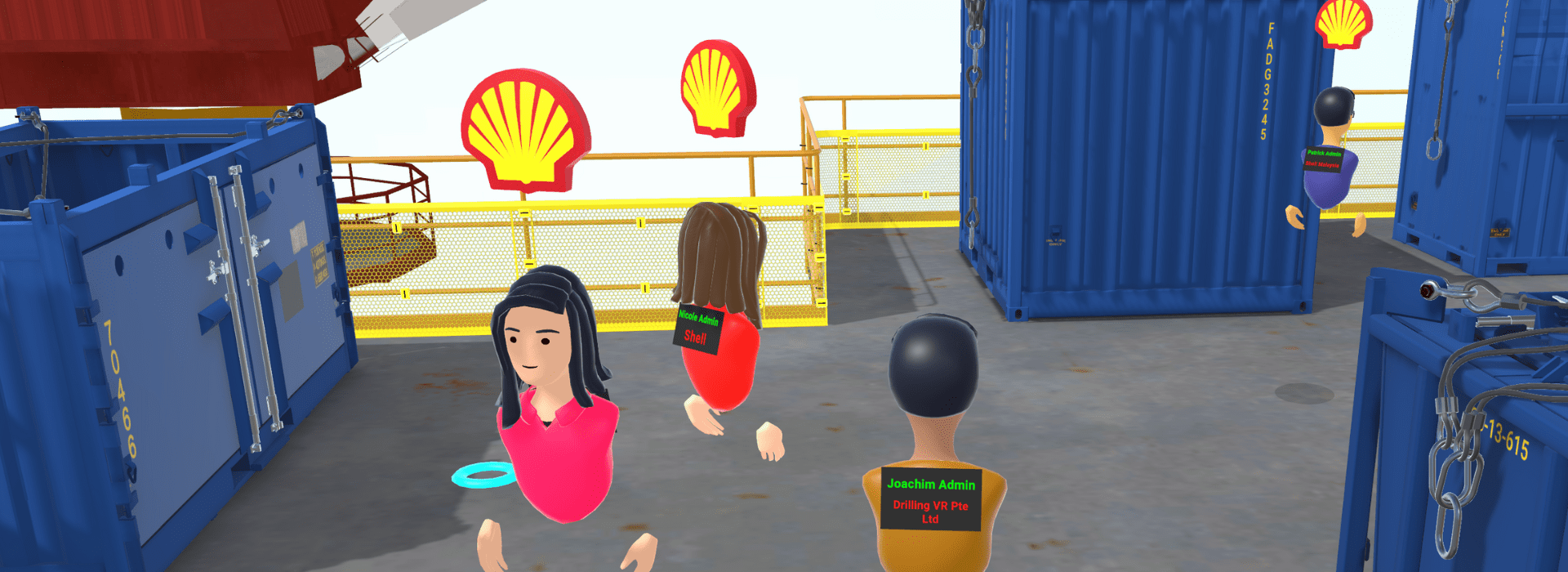

Administrative controls aim to change behavior. Regular risk assessments become essential, pinpointing potential hazards in advance. DROPS Training sessions ensure workers are equipped with best practices. Furthermore, safety zones, such as Red Zones & No-Go areas, become standard, marking potential hazard zones.

Personal Protective Equipment (PPE): The Last Resort

PPE acts as the final barrier between a worker and potential hazards. Hard hats, safety boots, and high-visibility vests can reduce the impact of a falling object. However, it’s essential to understand that PPE is the last line of defense. The goal should always be to prevent the drop, not just to reduce the injury.

The Real-World Impact of the Hierarchy

The Hierarchy of Controls isn’t just a theoretical concept. By starting with elimination and working down the hierarchy, organizations can address the root cause of the hazard rather than just its symptoms. Initial investments in controls can lead to long-term benefits in terms of reduced incidents, medical costs, equipment damage, and operational downtime.

Conclusion – DROPS Hierarchy of Controls

The Hierarchy of Controls offers a clear path to navigate the challenges of dropped objects in industrial settings. By understanding and applying each level of the hierarchy, industries can create a comprehensive strategy that addresses the root causes of risks, ensuring a safer and more efficient workspace.