Dropped Objects in Industrial Operations: Unpacking Definitions and Implications

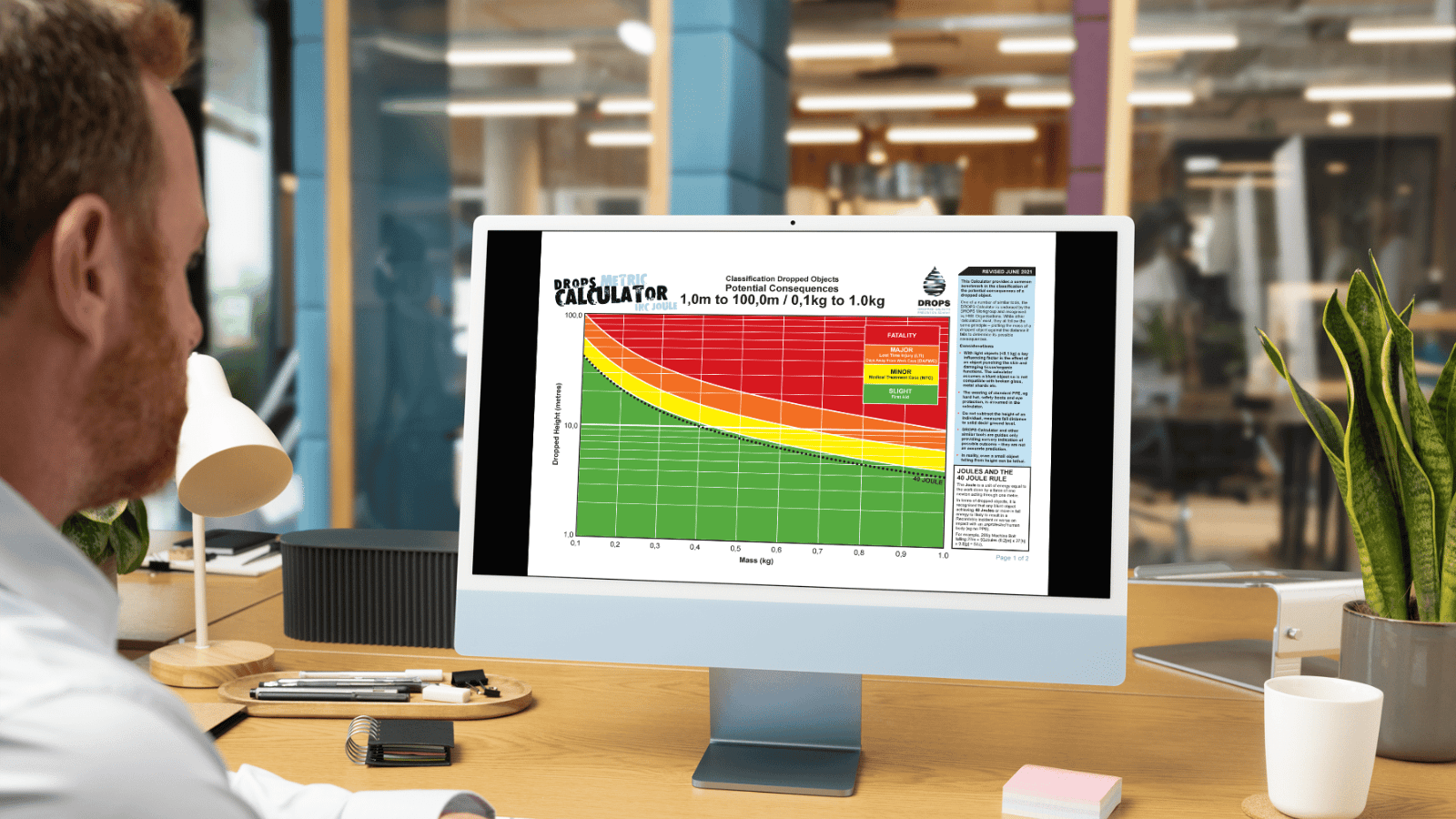

In industrial operations, seemingly minor incidents like dropped objects can lead to significant consequences. At first glance, you might dismiss a dropped object as a trivial event. However, when you factor in the heights and environments of many industrial tasks, the potential dangers become clear. An object, whether small like a component or larger like a piece of equipment, can cause serious damage or injury when it falls.

1. Dropped Object:

This term defines any item that can cause injury, death, or damage to equipment or the environment when it falls from its original position. Several factors amplify the danger of a dropped object:

- Height: Objects falling from great heights can gather tremendous force, leading to severe damage or injury upon impact.

- Environment: Industrial settings often have machinery, equipment, and personnel. A dropped object can damage its immediate impact point and can also trigger a chain reaction, causing more harm.

- Nature of the Object: Objects that are sharp, heavy, or hot pose additional risks.

2. Dynamic Dropped Object:

This refers to any object that falls due to applied forces. These forces can come from other equipment impacts, machinery, moving items, or even external factors like severe weather. The unpredictability of these objects’ trajectory and impact makes them especially dangerous. Common scenarios leading to dynamic dropped objects include:

- Equipment Malfunction: A malfunctioning machine can send parts flying.

- External Forces: In outdoor industrial settings, strong winds can dislodge objects.

- Human Error: Mishandling equipment or tools can result in falls, especially when subjected to force.

3. Static Dropped Object:

These objects fall due to gravitational or natural forces, without any external force. For example, a connection that isn’t bolted properly can give way over time. Risks associated with static dropped objects often arise from:

- Improper Securing: Objects not fastened or stored correctly can fall. For instance, a weakly bolted connection on a platform might collapse.

- Natural Degradation: Fixtures or fastenings can corrode or wear out over time, causing objects to fall.

- Environmental Factors: Vibrations, temperature changes, or moisture can dislodge objects without direct force.

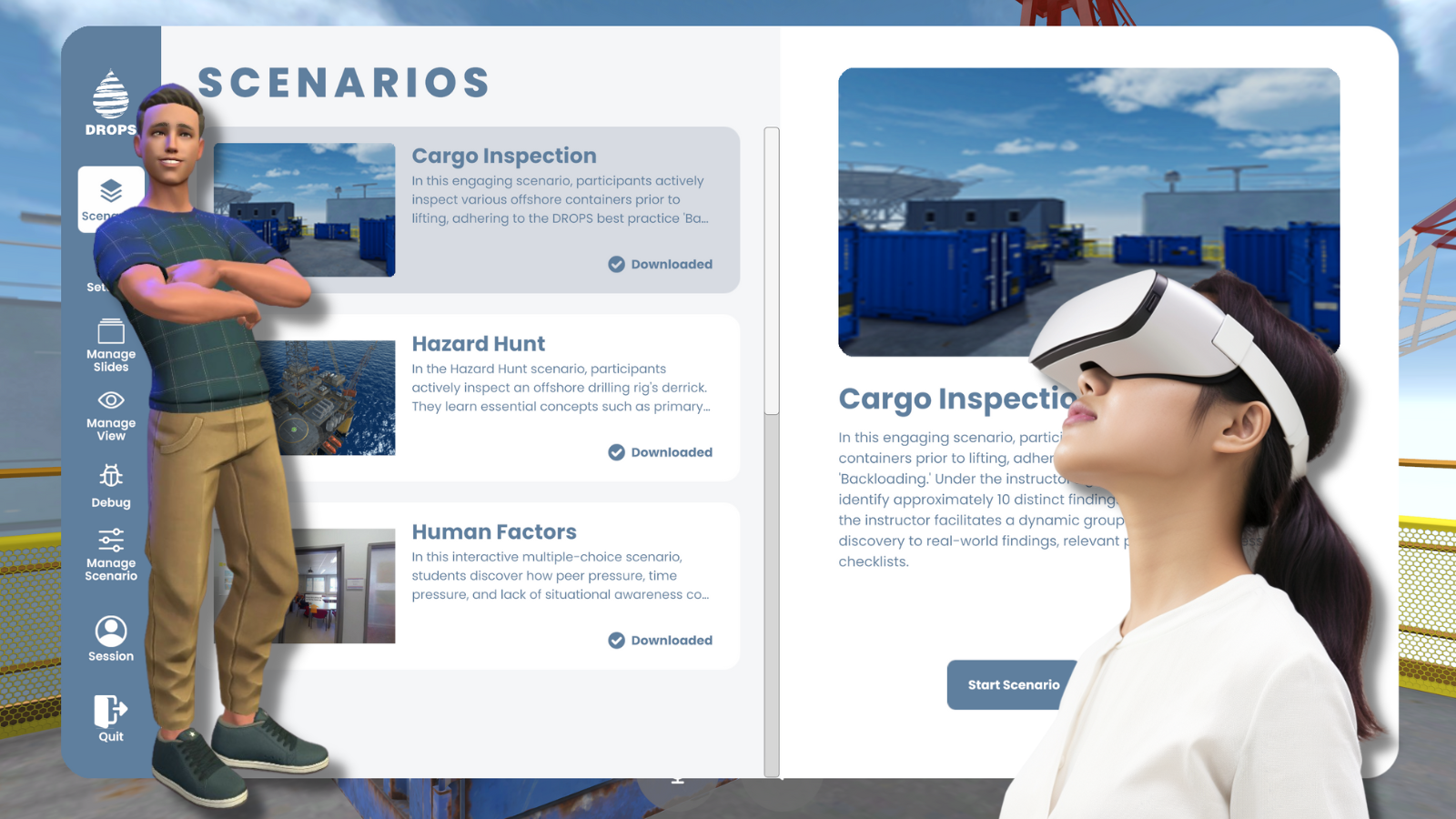

Moving Forward

To recognize the dangers of dropped objects in industrial settings, we must understand their nature and causes. By doing so, industries can take targeted preventive measures. Regular inspections, worker training, and investing in quality equipment stand out as effective ways to reduce these risks. As industries evolve, they must adopt a proactive safety approach, rooted in a deep understanding of risks, to protect both personnel and assets.